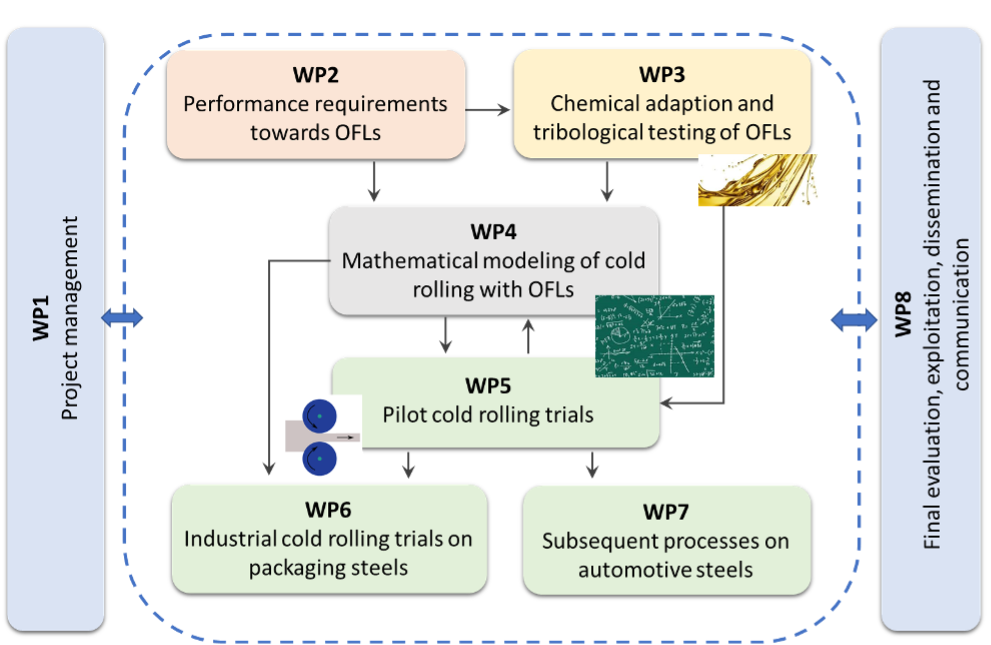

The project is divided into 8 complementary and related work packages (WPs) with a duration of 42 months.

WP1 covers the project management work including the coordination, the organisation of meetings with the partners, project monitoring and evaluation, financial management and the reporting work. All partners are involved in this WP.

In WP2 OFL requirements for different final use-cases will be defined by TKPS and TKSE. The necessary parameters to characterise the lubricant will be set in this work package. In addition, the current emulsion will be characterised as basis for later comparison.

In WP3 QH will be in charge of the adaptation of OFL components for setting the required property profile and further adjustment of the OFLs with focus on the steel processing. The characterisation of the adapted OFLs will be performed by QH and BFI. Tribological trials, lubricant performance, maintenance and care characteristics will be carried out together by BFI and QH. In addition, the evaluation of the chemical stability of the current emulsion and OFL will be done in this WP by QH. The adjustment necessary for the monitoring with OFL will be assessed here as well.

In WP4 SSSA will adapt existing mathematical models for the cold rolling towards OFLs (1) which will be used for the pilot trials and (2) will enable the design of the industrial trials that take place at TKPS. The model will be a powerful support tool for TKPS, Tata and QH, especially for the latter in its innovative OFL adaption activity and to extend and deepen the knowledge on OFLs.

In WP5 cold rolling trials with selected OFLs and with three steel grades (2 automotive and one packaging steels) will be carried out at the Tata Steel pilot mill. It is planned to test in a first stage 3-4 OFLs to get a first impression on their performance and in a second step up to 3 OFLs, further improved based on the results of the first step. These trials will be performed with extensive testing. Together with the cold rolling trials, the lubricant performance, the maintenance, care and wastewater treatment related characteristics will be evaluated. Finally, these pilot trials will enable to deduct the requirements for a successful transfer into the industrial scale.

In WP6 the requirements for the restructuring of the cold rolling mills as well as the further downstream processes will be at first instance provided. After the cold rolling trials at the pilot plant of Tata Steel, the best OFL will be selected and cold rolling trials will be carried out at TKPS with packaging steels. The rolled coils performed with OFL will be investigated up to the coating process at TKPS.

In WP7 after the cold rolling trials at the pilot plant of Tata Steel, the OFL-rolled coils of automotive steels will be further investigated in the subsequent processes (degreasing, annealing, skin-pass rolling and coating) at TKSE. These processes will be assessed at different scales: degreasing, skin-pass rolling and coating trials will be done at pilot scale and the annealing trials at industrial scale.

In WP8 the technical feasibility to restructure a cold rolling mill with OFL will be evaluated and guidelines will be provided. In addition, a cost evaluation regarding the successful transfer of OFLs into the industry will be carried out and the economic and ecological benefits will be assessed in this work package. Exploitation, dissemination, and communication activities will be carried out in this WP.